Waste-to-Energy Plants: Technology, Cost, and Benefits

Published on: January 6, 2026

As the world grapples with rising waste volumes and energy demands, Waste-to-Energy (WtE) technology offers a sustainable solution that converts solid waste into usable electricity and heat. These plants help reduce landfill dependency, lower greenhouse gas emissions, and generate renewable energy. This comprehensive guide explores how Waste-to-Energy plants work, the main technologies used, investment requirements, operational benefits, and future prospects in the global energy landscape.

1. Introduction to Waste-to-Energy (WtE)

Waste-to-Energy (WtE) refers to a process that transforms non-recyclable municipal and industrial waste into usable forms of energy — typically electricity, heat, or fuel. Instead of sending waste to landfills, WtE facilities harness the energy potential of materials such as plastics, paper, and organic waste through advanced combustion, gasification, or biochemical conversion methods.

In addition to generating power, WtE systems contribute to sustainable waste management, reduce environmental pollution, and support circular economy goals by converting waste into valuable resources.

2. Why Waste-to-Energy is Important

The global population produces over 2 billion tonnes of municipal solid waste annually, much of which ends up in landfills. Landfills not only occupy valuable land but also emit methane — a potent greenhouse gas. Waste-to-Energy technologies help address these challenges by:

- Reducing landfill waste and extending landfill lifespan.

- Converting waste into renewable electricity and heat.

- Lowering greenhouse gas emissions.

- Recovering metals and other valuable by-products from ash residues.

- Contributing to national renewable energy targets.

3. Types of Waste Suitable for Energy Conversion

Not all waste is suitable for WtE processes. The following categories are typically used:

- Municipal Solid Waste (MSW): Household and urban waste containing organic and combustible materials.

- Industrial Waste: Non-hazardous manufacturing by-products and packaging materials.

- Agricultural Waste: Crop residues and animal manure for biogas generation.

- Plastic and Rubber Waste: Non-recyclable plastics with high calorific value.

- Sewage Sludge: Used in anaerobic digestion to produce biogas.

Proper segregation and preprocessing improve energy recovery efficiency and minimize harmful emissions.

4. Waste-to-Energy Conversion Technologies

Several technological pathways exist for converting waste into energy. The choice depends on waste type, desired output, and environmental regulations.

4.1 Incineration (Mass Burn)

This is the most common WtE method. Waste is burned at high temperatures (850–1,100°C) to produce heat, which generates steam and electricity. Modern incineration systems include filters and scrubbers to minimize pollutants.

4.2 Gasification

Waste is heated in a low-oxygen environment to produce syngas (a mix of hydrogen and carbon monoxide). Syngas can be used to generate power or converted into synthetic fuels. Gasification achieves higher energy efficiency and lower emissions than traditional incineration.

4.3 Pyrolysis

In this process, organic waste is decomposed at 400–800°C without oxygen, producing bio-oil, syngas, and char. Pyrolysis is suitable for plastic and rubber waste management and offers potential for liquid fuel recovery.

4.4 Anaerobic Digestion (Biochemical Method)

Organic waste is broken down by bacteria in an oxygen-free environment, producing biogas (mainly methane and CO₂) and digestate (a nutrient-rich byproduct). Biogas can be used for heating, electricity, or upgraded to biomethane for use as vehicle fuel.

4.5 Refuse-Derived Fuel (RDF)

Non-recyclable, high-calorific-value waste materials are shredded and dried into solid fuel pellets. RDF can be co-fired in cement kilns or power plants as a substitute for coal.

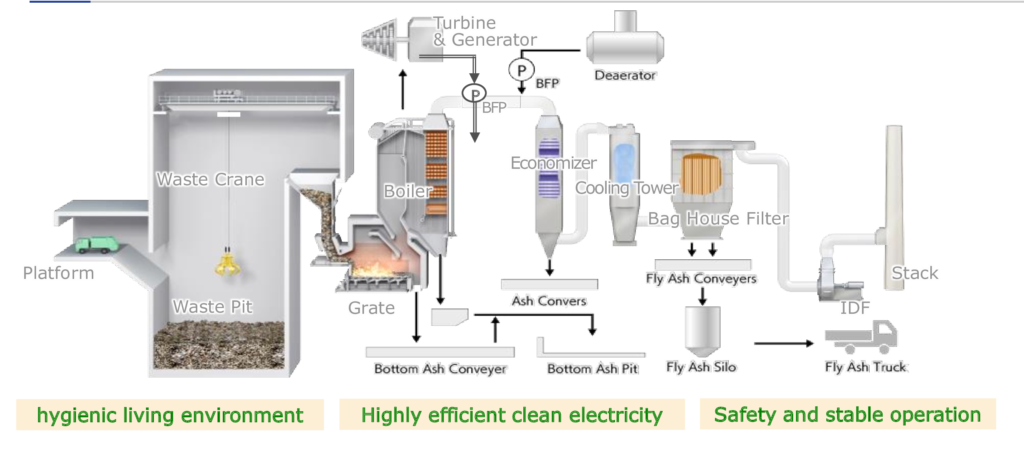

5. Step-by-Step Working of a Waste-to-Energy Plant

The typical process flow in a WtE facility involves several stages:

- Waste Collection and Transportation: Waste is gathered from municipal or industrial sources and delivered to the plant.

- Segregation and Preprocessing: Recyclables and inerts (glass, metals) are removed. Remaining waste is shredded and dried if necessary.

- Combustion or Conversion: The waste undergoes thermal or biochemical conversion to release energy.

- Energy Recovery: Heat produced is used to generate steam, which drives turbines to produce electricity.

- Emission Control: Filters and scrubbers remove particulates, dioxins, and harmful gases before exhaust release.

- Ash and Residue Treatment: Bottom ash may be used in construction materials after metal recovery; fly ash is disposed of safely.

6. Cost of Setting Up a Waste-to-Energy Plant

The cost of building and operating a WtE plant depends on technology type, waste volume, and local regulations. Below is a general estimate:

| Plant Capacity | Technology | Approx. Investment (USD) | Estimated Operating Cost (per ton of waste) |

|---|---|---|---|

| 100 TPD (Small) | Incineration / RDF | $5 – $10 million | $30 – $50 |

| 300 TPD (Medium) | Gasification / Pyrolysis | $15 – $30 million | $40 – $70 |

| 1000 TPD (Large) | Mass Burn Incineration | $50 – $100 million | $60 – $100 |

Additional costs may include land acquisition, waste collection systems, emission control equipment, and grid connection infrastructure. However, revenue from power sales, tipping fees, and recovered materials offsets some expenses over time.

7. Sources of Revenue from WtE Plants

Waste-to-Energy projects generate multiple income streams, including:

- Electricity sales to the grid or industries.

- Heat supply for district heating or industrial use.

- Tipping fees from municipalities for waste disposal.

- Recycling and sale of recovered metals from ash.

- Carbon credits for emission reduction under environmental programs.

8. Environmental and Social Benefits

WtE plants deliver several environmental and community benefits:

- Reduced Landfill Waste: Up to 90% reduction in landfill volume.

- Renewable Energy Production: Provides clean electricity and heat from waste materials.

- Lower Greenhouse Gas Emissions: Avoids methane generation from decomposing waste.

- Resource Recovery: Extracts valuable metals and aggregates from ash residues.

- Employment Opportunities: Creates skilled jobs in waste management, operations, and maintenance.

9. Challenges and Limitations

Despite its advantages, the WtE sector faces certain obstacles:

- High capital investment and operational costs.

- Complex permitting and regulatory compliance requirements.

- Public opposition due to emission concerns.

- Need for consistent waste supply and quality.

- Competition with recycling initiatives for waste feedstock.

Proper project design, transparent communication, and advanced pollution control systems can mitigate these challenges effectively.

10. Emission Control and Environmental Regulations

Modern Waste-to-Energy facilities adhere to strict emission standards. Technologies such as:

- Bag filters and electrostatic precipitators for dust removal.

- Lime scrubbers for acid gas neutralization.

- Activated carbon injection to capture dioxins and heavy metals.

- Continuous emission monitoring systems (CEMS) for real-time data tracking.

Compliance with local environmental standards (e.g., EU Industrial Emissions Directive, U.S. EPA standards, or CPCB guidelines in India) ensures safe and sustainable operations.

11. Global Case Studies

1. Spittelau Waste-to-Energy Plant (Vienna, Austria): A landmark facility known for its energy efficiency and architectural design, processing over 250,000 tons of waste annually to provide district heating.

2. Shenzhen East Waste-to-Energy Plant (China): One of the world’s largest WtE plants, capable of processing 5,000 tons per day with advanced emission control and power generation systems.

3. Brescia Waste-to-Energy Plant (Italy): Uses combined heat and power (CHP) technology to supply electricity and heat to over 150,000 households.

4. Okhla WtE Plant (India): Processes municipal waste from Delhi, generating up to 16 MW of electricity, contributing to India’s renewable energy goals.

12. Government Policies and Incentives

Many governments promote Waste-to-Energy as part of sustainable waste management strategies. Incentives include:

- Capital subsidies or low-interest loans for WtE plant setup.

- Feed-in tariffs for renewable electricity generation.

- Tax rebates for environmental infrastructure projects.

- Public-private partnership (PPP) schemes for waste processing facilities.

- Carbon credit programs under Clean Development Mechanism (CDM).

Countries like Japan, Germany, and Sweden have integrated WtE into their national energy mix, achieving both waste reduction and renewable energy expansion goals.

13. Future Outlook and Technological Innovations

The future of Waste-to-Energy is shaped by innovation, digitalization, and environmental integration. Emerging trends include:

- AI and IoT Integration: Smart monitoring systems optimize energy output and reduce downtime.

- Advanced Gasification Reactors: Produce cleaner syngas for hydrogen and synthetic fuel generation.

- Hybrid WtE-Solar Systems: Combine renewable sources for continuous energy generation.

- Carbon Capture and Utilization (CCU): Captures CO₂ from flue gas for industrial reuse.

- Circular Economy Integration: Encourages recycling, reuse, and energy recovery in a single framework.

These advancements are making WtE plants cleaner, more efficient, and economically viable across diverse markets.

14. Conclusion

Waste-to-Energy plants represent a vital intersection of waste management and renewable energy production. By converting solid waste into valuable energy, they help address landfill overflow, reduce emissions, and support sustainability goals. While setup costs and environmental compliance present challenges, technological improvements and supportive government policies are making WtE solutions increasingly accessible and efficient.

As global energy needs grow and environmental awareness deepens, Waste-to-Energy will play a pivotal role in shaping a cleaner, more circular, and sustainable future.

Disclaimer: This article is for informational purposes only. Costs and regulations may vary by country and region. Always consult environmental authorities and technical experts before investing in Waste-to-Energy projects.

© 2026 GreenTech Insights. All rights reserved.